LATASCREED® 100

A factory-prepared blend of selected raw materials, Portland cement and graded fillers.

LATASCREED® 100

A factory-prepared blend of selected raw materials, Portland cement and graded fillers.

Colour:

Grey

SKU:

Compliance:

EN 13813

Designation CT-C25F3B1.5SH40

Product Overview

LATASCREED® 100 is formulated to meet and exceed both national and international standards. This blend is ideal for creating durable screed that are perfect for a variety of floor applications.

The unique composition of LATASCREED® 100 ensures high strength and excellent water retention, making it self-curing and suitable for both interior and exterior use.

Product Details

Specifications

Designation CT-C25F3B1.5SH40

VOC: Nil

Substrates

Concrete

Cement Mortar Beds

Cement Terrazzo

FAQs

LATASCREED® 100 is a factory made underlay cement concentrate which is engineered to produce high strength screed / mortar with water and aggregates at site for use in internal and external floors. It is designed to produce and lay bonded, un-bonded or floating screed.

You can use LATASCREED® 100 for internal and external areas like residential floors, commercial floors and industrial floors, parking lots etc.

For 25 Kg bag of LATASCREED® 100, one needs 8 to 12 Litres of water. Mix water depending upon the consistency of mix required and ambient environmental conditions.

Yes. One can lay the screed made with LATASCREED® 100 before installation of tiles, stones, carpets, vinyl flooring or wooden flooring.

Tiles can be laid in the traditional methodology (Wet on Wet system) using MYK LATICRETE Super Set Slurry. One can also wait for 3 days after laying the screed to install tiles/stones using adhesive. Both the methods offer great advantage over normal cement screed which results in very well bonded tiles/stones without hollow sounds and chipping or popping of tiles/stones.

The cement screed would require water curing for a minimum period of 11 days for gaining complete strength.The screed made with LATASCREED® 100 doesn’t require water curing and has better workability, compaction and finish. This is part of MBS system due to this distinct advantage. It is a great advantage when high absorbent natural stones are being installed on floors, there is absolutely no moisture present when the underlay is made with LATASCREED® 100.

MBS system is Moisture Barrier System which is the proprietary system from MYK LATICRETE India. This is especially for natural stones which develop stains due to their porosity and absorption of liquids. LATASCREED® 100 does not require water curing which makes the screed dry without moisture and hence natural stones are not stained due to screed moisture.

Yes. One can use crushed sand, stone dust or artificial sand for making screed with LATASCREED® 100.

One can make a bonded screed / un-bonded screed up to 70mm with LATASCREED ®100 with ease.

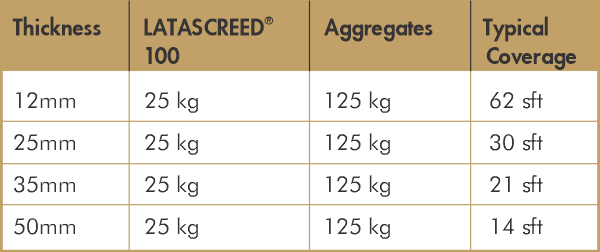

When one wants high strength screeds, the proportion would be 1:3 (LATASCREED® 100: aggregates). One can go up to 1:8 proportion for low strength screed. It is important to check the strength of screed with a control sample made with LATASCREED® 100 and the local aggregates before commencing the work on large areas.

The precautions before laying the LATASCREED ®100 screed are:

- Use good quality water to mix the screed

- Ensure concrete surface is cleaned without debris, curing compounds, dust or any other contaminants.

- Pre-wet the concrete surface to ensure Surface saturated Dry conditions (SSD condition)

- Key coat (Priming coat) should be done using LATASCREED® 100 mixed with water to form slurry ensuring minimum 1 Kg consumption per Square Meter area of floor.

- Mix the screed materials using LATASCREED ®100 uniformly without any lumps. Check the consistency of screed.

- Place the mixed materials of screed made with LATASCREED® 100 when the key coat is still tacky.