As the world moves towards a more sustainable future, it is becoming increasingly important to consider eco-friendly methods of construction. One such method of construction is 3D concrete printing, which has the potential to save tremendous amounts of energy and reduce the need for new construction materials.

We’ll also discuss the various applications of 3D concrete printing and its potential future as a construction method. So, stay tuned!

What is 3D Concrete Printing?

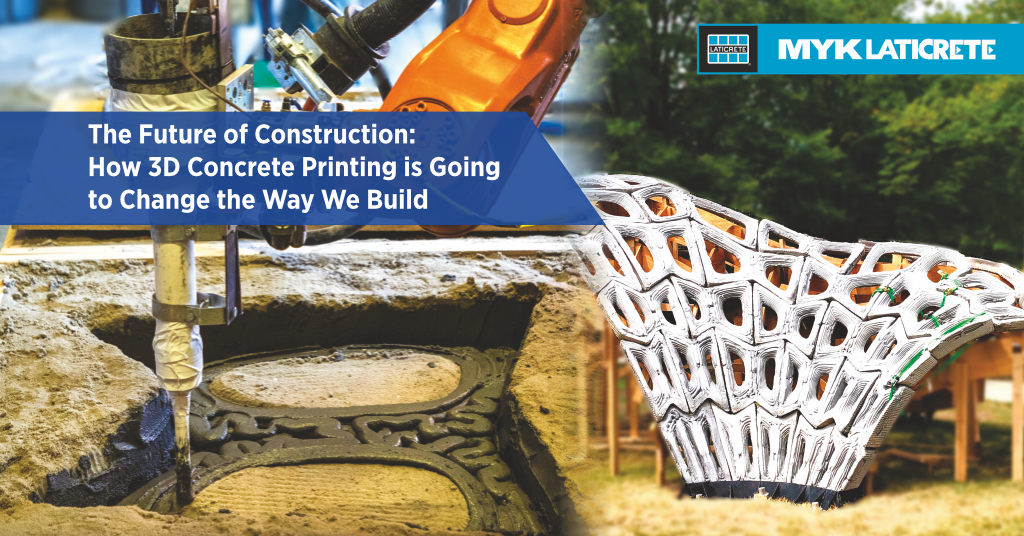

3D Concrete Printing is an innovative technology that uses multiple layers of concrete to create structures and products. It’s a fast, efficient way to create large-scale objects, like buildings or sculptures. The process is like how we make traditional concrete, but with the added ability to print in multiple colours and textures. There are many potential applications for this technology, including the construction industry and hobbyist projects alike! So, if you’re curious about how 3D Concrete Printing works!!!

How is 3D Concrete Printing made?

3D Concrete Printing is a technology that has been making waves in construction and design circles for years. It’s a process that allows for the printing of layers of concrete together to create a three-dimensional object. This technology has several advantages over traditional methods like brick-and-mortar construction. For example, 3D Concrete Printing is environmentally friendly as it doesn’t require the use of any form of cement. Additionally, it’s faster and easier to construct. So, if you’re looking to get creative with your construction projects, or want to explore new design possibilities, 3D Concrete Printing is the perfect technology for us!

What are the major applications for 3D printing in concrete?

In the construction industry, 3D Printing has many applications. The main application is for printing complex structures in one go. This means that the time taken to build a structure can be reduced drastically and it also enables the usage of materials which are not available or not feasible to be used in traditional construction techniques.

There is a lot of potential for 3D Printing to change the traditional building process completely as it allows architects and designers alike to print structures out of any material they choose; in any shape they choose. This means that there is no need to use concrete anymore because it can just be replaced with another material.

3D concrete printing is a cutting-edge technology with great potential for the construction industry. In our case studies, we have demonstrated the feasibility of using 3D concrete printing to create complex structures quickly and efficiently. We believe that this technology has great potential, and we will continue to explore its applications.

Why do we need 3D Concrete Printing ?

There are several reasons why 3D concrete printing is seen as a valuable technology in the construction industry:

Speed and efficiency: 3D concrete printing allows for the rapid construction of complex structures, reducing the time and labour required to build them. This can lead to significant cost savings and faster completion of projects.

Customization: 3D concrete printing allows for the creation of unique and complex architectural designs that would be difficult or impossible to achieve using traditional building methods. This can lead to more visually appealing and functional buildings.

Sustainability: 3D concrete printing can help to reduce waste and improve energy efficiency in the construction process. The technology allows for the precise use of materials, reducing the amount of excess concrete and other materials that would otherwise be discarded.

Flexibility: 3D concrete printing can be used to create structures of various shapes and sizes and can be applied in different environments. This makes it a versatile technology that can be used in a wide range of construction projects.

Remote construction: 3D concrete printing can be used to build structures in remote areas, reducing the need to transport heavy materials and labor. 3D printing technology offers unique opportunities in a variety of fields, Thus, in both construction and entertainment, advanced technology is making convenience and accessibility possible for users by reducing distances and overcoming borders.

Cost-effective: 3D Concrete printing can be used to construct buildings at a lower cost than traditional methods, by reducing labour costs and material waste.

Safety: 3D Concrete printing can help to improve safety on construction sites by reducing the need for workers to perform dangerous tasks, such as working at heights.