Beauty in any form arrests one’s gaze. We live in a world covered with beautiful things. From architectures, hotels, studios, malls to homes, lobbies and others, everything around is designed to enthrall us. Every structure flashes out one particular aspect that makes it stand out. Let’s focus on a hotel lobby. Have you ever wondered where does a hotel lobby get its charm from? Apart from the fancy couch, what makes a hotel lobby stand out? Keep reading to find out.

The interior design of a particular place matters most. Unlike homes, hotel lobbies consider a different style of interior designing. Fixing of large format/slim tiles is in vogue today. Don’t you agree? Walk by any hotel lobby and you’ll notice most of them have large tiles fixed on their walls, which leaves you in awe. Large tiles not only enhance the look of the interior but also make the lobby look spacious and classy. The market offers various types of tiles to complement any type of structure. Fancy tiles are used to design both interiors and exteriors of a particular structure.

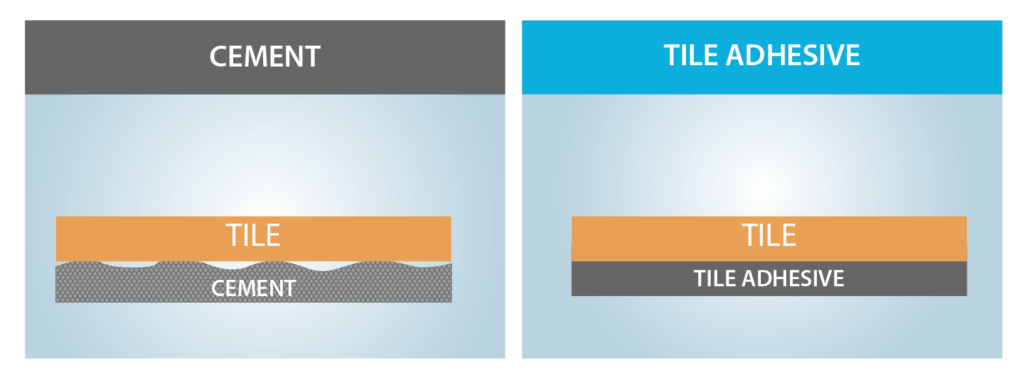

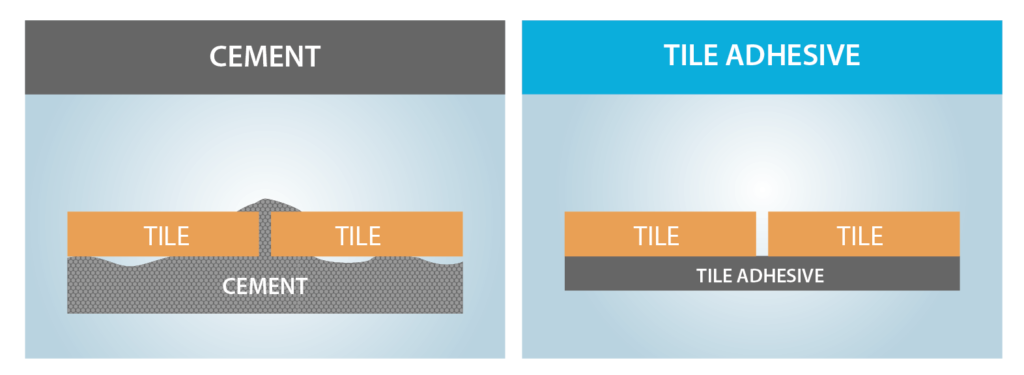

It may all sound easy-peasy. But, as easy as it may seem to choose a tile pattern, is it the same for fixing it? Let’s get into the nitty-gritty of fixing large format/slim tiles on any surface. Fixing large format/slim tiles is a challenge; there are instances of it chipping off, cracking, etc. if not fixed well. What if you were told fixing large format/slim tiles is now easier than ever? Stunned? Don’t be. MYK LATICRETE understands your every need, and thus presents to you an adhesive that’s the ideal one for installation of large format/slim tiles on any substrate. With maximum strength, this adhesive helps hold large format/slim tiles on any type of surface.

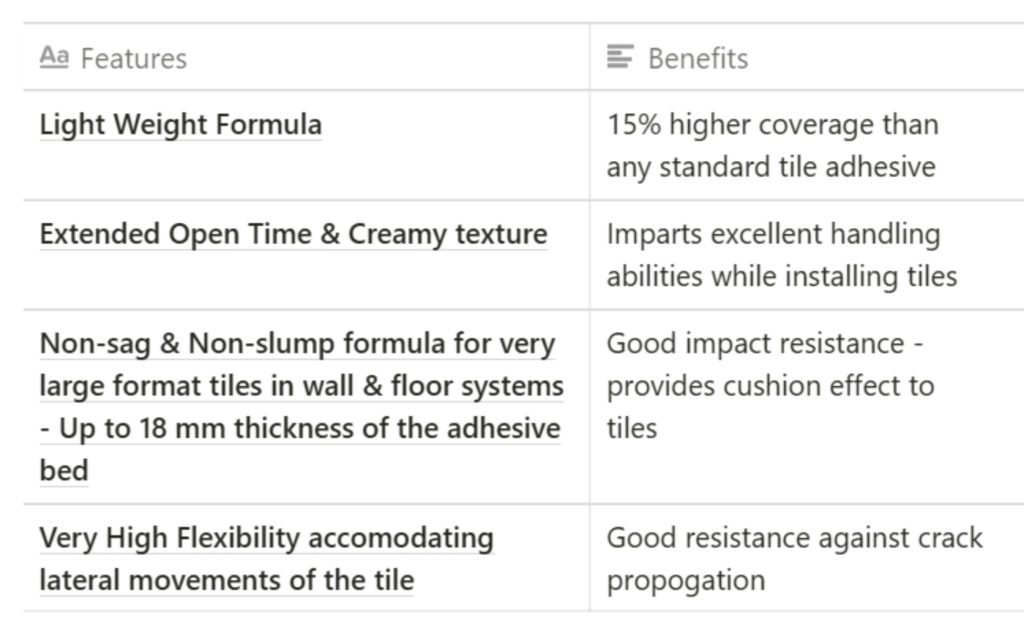

From hotel lobbies, building facades to any other structure that requires fixing large tiles or slim tiles, this is your go-to adhesive – MYK LATICRETE 335 MAXI. This is a flexible, shock-resistant, specially formulated tile adhesive that’s capable of providing reliable bonding. It is an ideal adhesive for large format/slim tiles for interiors and exteriors. It also withstands extreme weather conditions.

Fret no more about fixing large format/slim tiles, with MYK LATICRETE 335 MAXI large format tiles and slim laminated tiles will stay the way you want.